18 8 Stainless Steel In Orthodontics

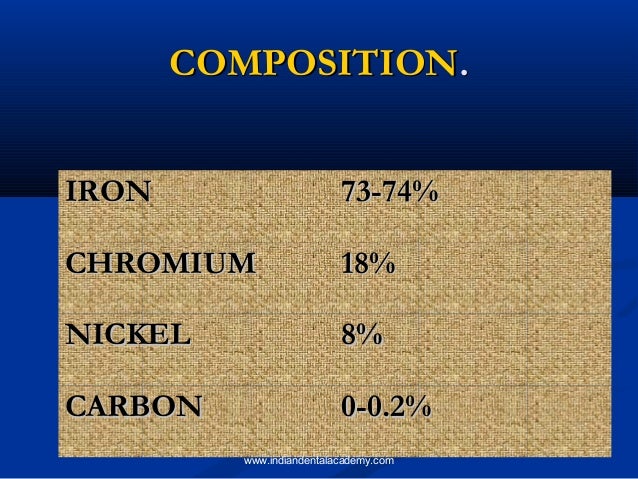

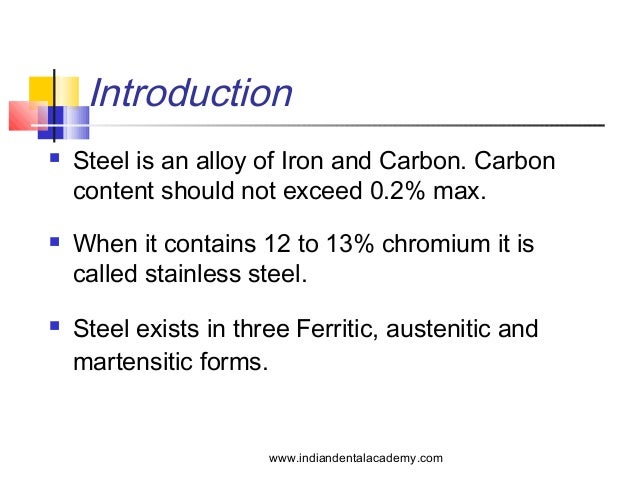

304 grade stainless steel is also comprised of no more than 0 8 carbon and at least 50 iron.

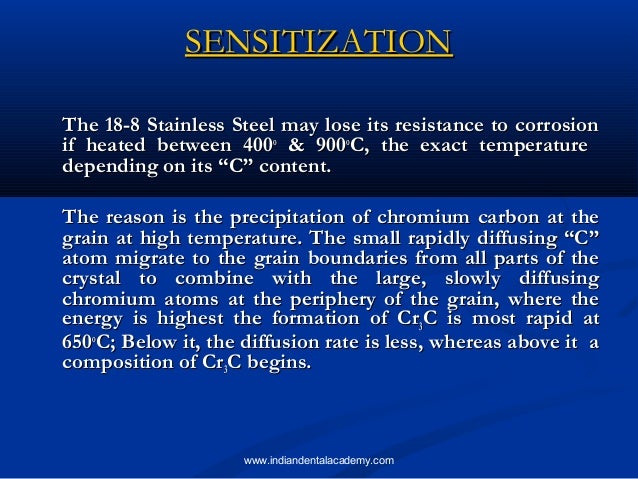

18 8 stainless steel in orthodontics. Type 304 has similar composition chief difference being that the carbon content is limited to 0 08. 18 8 stainless steel benefits from increased resistance to corrosion better than the 400 series. 18 8 stainless steel refers to the chemical composition of stainless steel containing 18 chromium cr and 8 nickel ni. Both 302 and 304 stainless steel may be designated as 18 8 stainless steel.

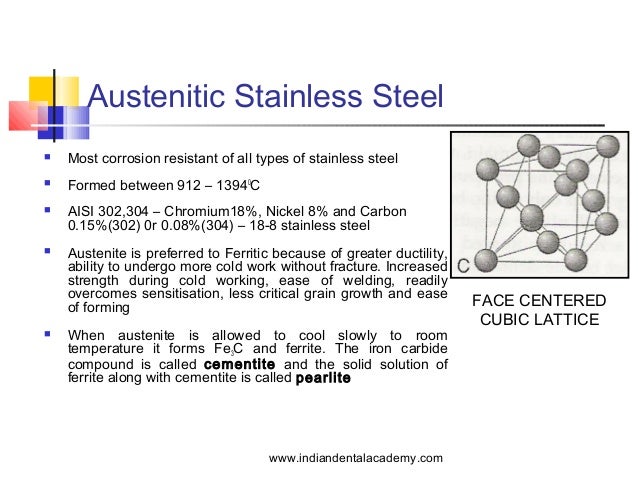

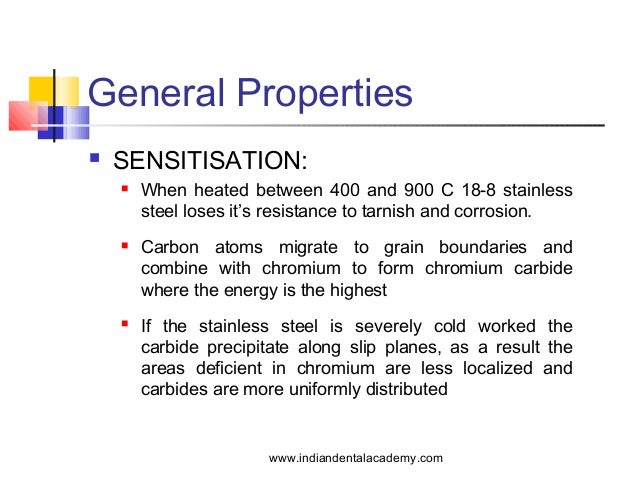

18 8 type stainless steel has better resistance to corrosion than the 400 series. Nickel also enhances the corrosion resistance of stainless steel. It can be hardened only by cold working and it isn t magnetic. The chromium binds oxygen to the surface of the product to protect the iron from oxidation rust.

For example 18 8 stainless steel is comprised of 18 chromium and 8 nickel. Therefore less heat can be conducted away from the weld area through the workpiece. They are the types most commonly used by the orthodontist in the form of band and wires. Chromium in this stainless steel alloy forms a thin oxide layer which blocks the diffusion of oxygen into the alloy and allow for the corrosion resistance of this alloy.

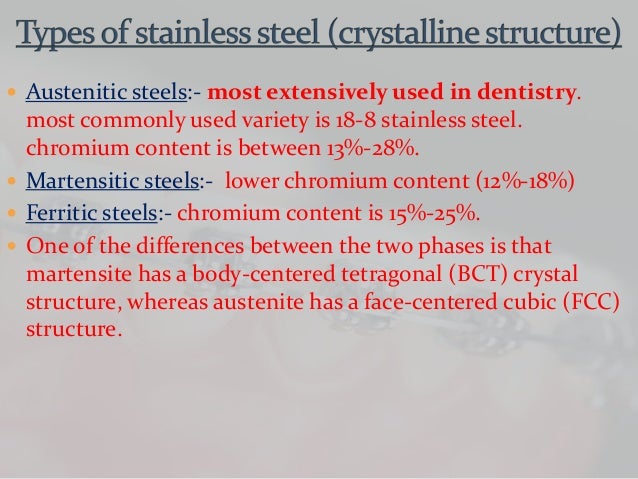

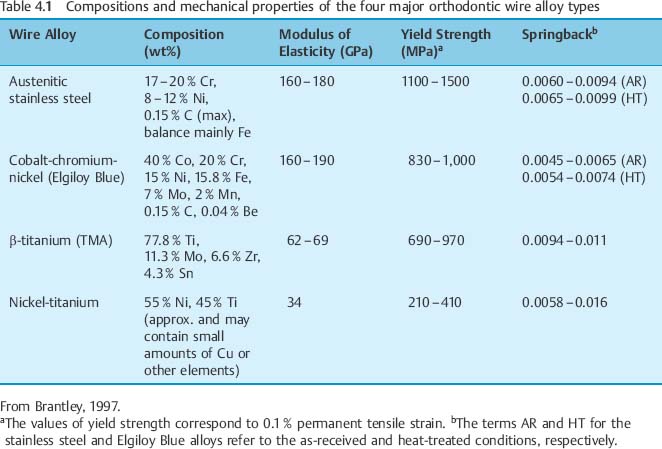

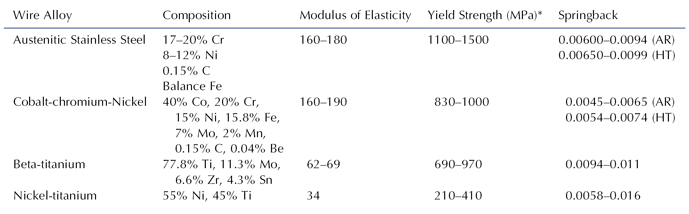

Austenitic stainless steels most corrosion resistant of stainless steels. 18 8 stainless steel is the most widely used austenite steel in the 300 series and is also known as the 304. Likewise mini implants besides titanium alloys are made by stainless steels and orthodontic wires which are mostly fabricated by stainless steels from types of 302 and 304 18 8 austenitic alloys. Austenite is pefered to ferritic because of greater ductility ability to undergo more cold work without fracture.

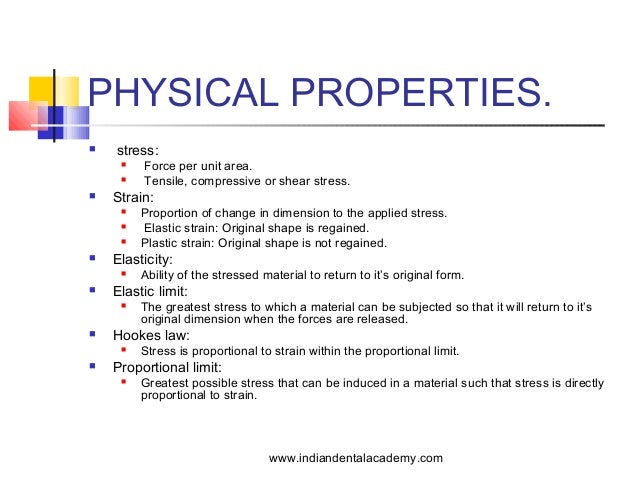

The poorer heat transfer of these materials contributes to the lower currents and shorter weld times are necessary for the development of an acceptable weld nugget. 300 series stainless steel has approximately 18 chromium 8 nickel. Standard 18 8 stainless steel includes ss 304 304l 304n 304ln 304h non standard 18 8 grade includes aisi 301 302 301l 301ln 302b etc. 18 8 stainless steel also offers a tensile strength range of 80 200 000 psi and good corrosion resistance.

Type 316l 0 03 maximum carbon is the type ordinarily employed for implants. Aisi 302 is the basic type containing 18 cr 8 ni and 0 15 carbon. The stainless steel alloys are of 18 8 austenitic type which contain chromium 17 25 and nickel 8 25 and carbon 1 2. The thermal conductivity of stainless steel is about 40 to 50 percent that of plain carbon steel.

Formed between 912 1394c aisi 302 304 18 chromium 8 nickel and 0 15 302 0r 0 08 304 carbon 18 8 stainless steel. This refers to the 300 series of stainless steel with a chromium and nickel content in percentages. 18 8 steel is the most widely used material has excellent corrosion. That means that an 18 8 grade fastener has 18 chromium and 8 nickel content.